Stock code: 601677

Stock code: 601677

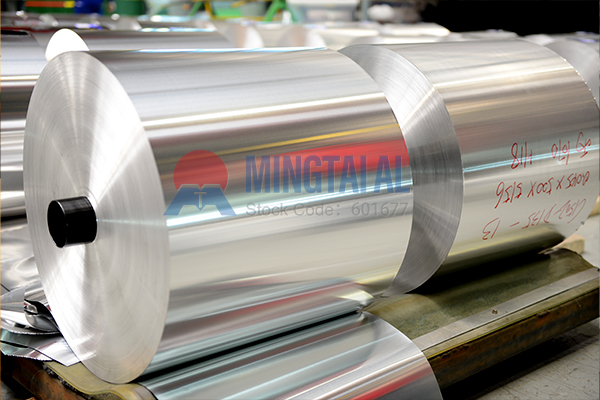

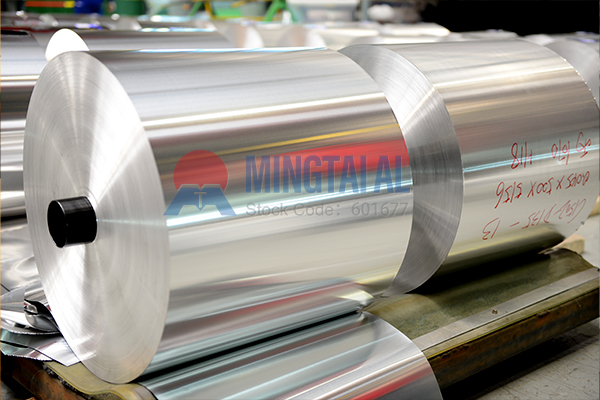

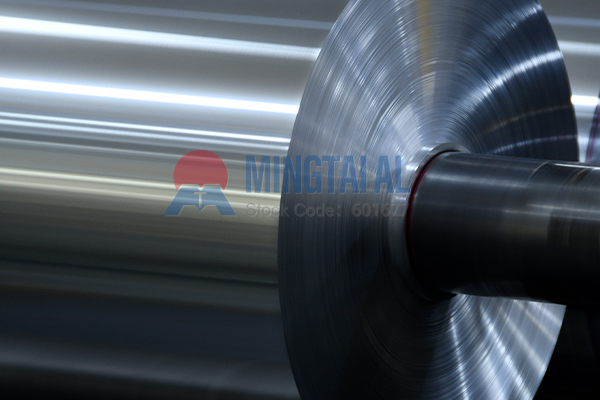

1060 aluminum foil is an industrial-grade pure aluminum foil (aluminum content ≥99.6%), combining high ductility with corrosion resistance, featuring a smooth surface free of oil residue.

1060 aluminum foil is an industrial-grade pure aluminum foil (aluminum content ≥99.6%), combining high ductility with corrosion resistance, featuring a smooth surface free of oil residue. Its excellent processing adaptability allows for ultra-thin rolling (minimum 0.014mm) and composite processes, enabling direct use without complex surface treatment. As a foundational aluminum foil material, 1060 is widely used in battery encapsulation, food packaging, and building insulation, offering a practical balance between performance and cost.

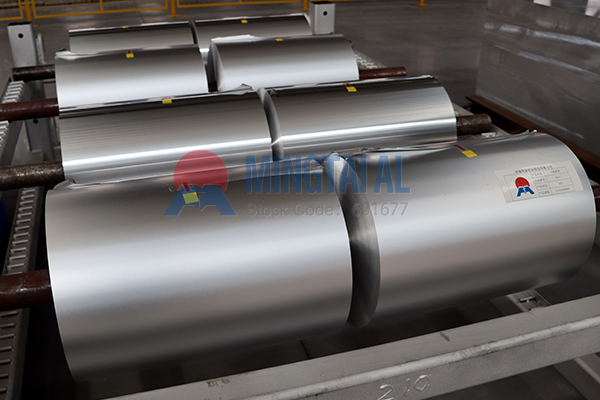

1060 aluminum foil is extensively applied in food packaging (e.g., chocolate, pharmaceutical anti-oxidation sealing), air-conditioning heat sink coatings, flexible battery packaging materials, and industrial thermal insulation protection. Its softness makes it suitable for inner layers of composite packaging or forming into foil containers to extend food shelf life. In industrial applications, it is often used as shielding material to block electromagnetic interference. Its ease of processing makes it an efficient and reliable solution for industries such as food, medical, and electronics.

|

Alloy |

1060 aluminum foil |

|

Temper |

O,H22,H24,H18,etc. |

|

Thickness (mm) |

0.018-0.20 |

|

Width (mm) |

100-1600 |

|

Length (mm) |

C |

|

Conductivity (% IACS) |

1060-O ≥ 61.5% IACS |

|

Surface |

Mill finish |

|

ID |

76mm,152mm,408mm,508mm or customized |

|

Standard |

ASTM-B-209M,BS EN 485-2,BS EN 573-3,GB/T3880-2008 |

|

Certificate |

Mill Test Certificate, Certificate of origin: Form A, Form E, CO |

|

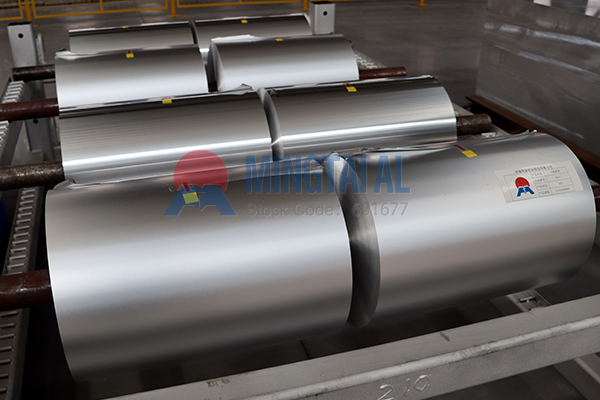

Package |

Export standard, Eye to sky or eye to wall |

|

Application |

Transformers, food packaging, capacitors, aluminum foil gaskets, electronic label lunch box materials, container foil, etc. |

≥99.6% aluminum content, compliant with food/pharmaceutical safety certifications.

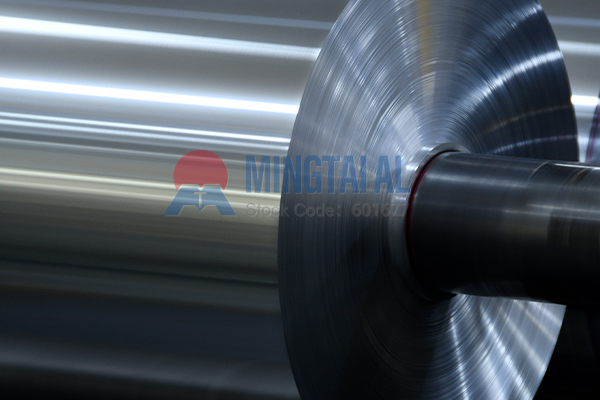

Supports rolling down to 0.006mm, meeting miniaturization demands for electronic components.

Resists acid/alkali corrosion, suitable for humid or high-salt industrial environments.

No alloying required, priced lower than alloy foils like 3003/8011.

"Our company uses 1060 aluminum foil as a reflective layer in solar thermal collectors. Its high reflectivity increases heat collection efficiency by 18%, and after two years of outdoor exposure, the foil shows no fading or cracking. With an additional thickened coating process, it now withstands extreme weather conditions flawlessly." — Technical Director, a New Energy Equipment Manufacturer