Stock code: 601677

Stock code: 601677

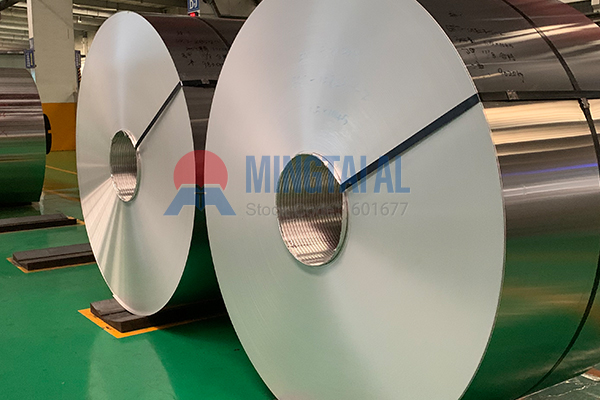

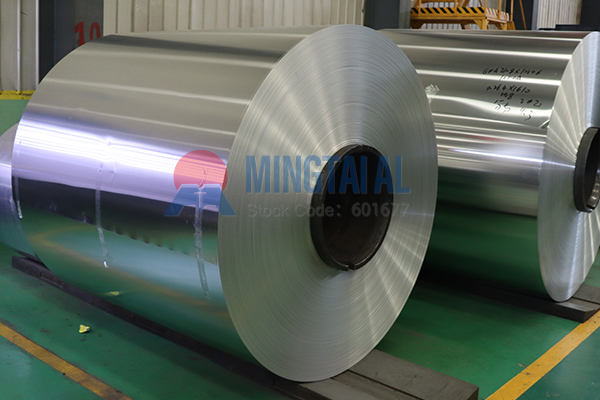

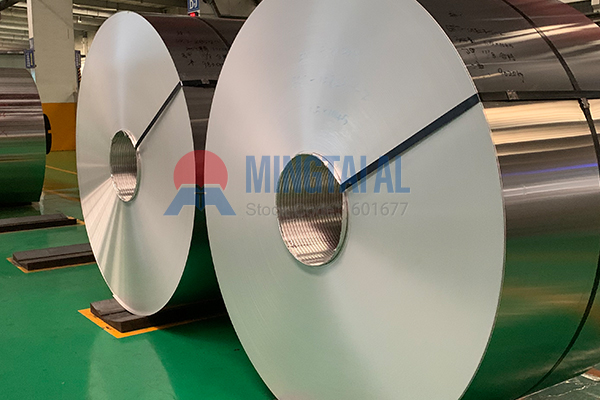

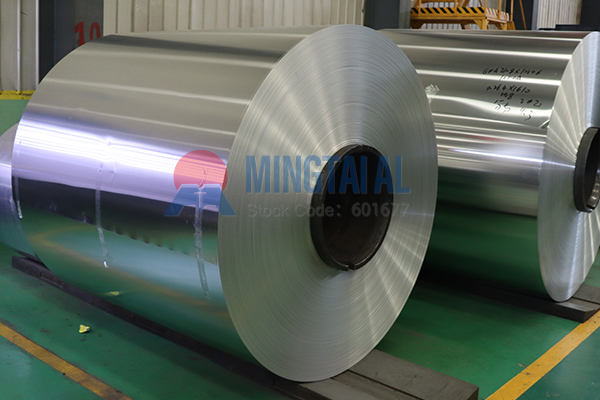

3104 Aluminum Coil is a manganese-strengthened aluminum-manganese alloy, where the addition of manganese enhances strength and toughness while retaining the lightweight properties of aluminum.

3104 Aluminum Coil is a manganese-strengthened aluminum-manganese alloy, where the addition of manganese enhances strength and toughness while retaining the lightweight properties of aluminum. Its dense surface oxide film provides superior corrosion resistance compared to ordinary aluminum, making it particularly suitable for humid or mildly acidic/alkaline environments. Compared to pure aluminum, 3104 aluminum coil offers better deep-drawing performance and tear resistance, resists cracking during processing, and maintains stable strength after welding. It is a cost-effective, mid-range aluminum solution widely used in food packaging, architectural decoration, and industrial component manufacturing.

1. Food Packaging: Used for manufacturing beverage can bodies, sealed can lids, and frozen food trays, complying with food safety standards.

2. Architectural Decoration: Applied in indoor ceilings, curtain wall partitions, and lightbox advertising substrates, with surfaces suitable for laminating or spraying.

3. Appliance Components: Ideal for refrigerator evaporators, air conditioner heat sinks, and microwave oven liners, offering corrosion resistance to extend equipment lifespan.

4. Industrial Containers: Used for chemical barrels, oil tank linings, and transport vehicle bodies, suitable for storing non-strongly corrosive media.

|

Alloy |

3104 aluminum coil strip |

|

Temper |

F,O,H12,H14,H16,H18,H19,H22,H24,H26,H28,H111,H112,H114,etc. |

|

Thickness(mm) |

0.2-10 |

|

Width(mm) |

100-2650 |

|

Length(mm) |

C |

|

ID |

Ø505mm or customized |

|

Package |

Eye to sky or Eye to wall |

|

Application |

Canning materials, oxidation materials, beer filling, cola filling, lamp head materials, shutters, LCD backplanes, cake trays, aluminum substrates for color coating, etc. |

|

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Zn |

Cr |

Others |

Al |

|

|

3104 |

0.60 |

0.70 |

0.05-0.20 |

1.00-1.50 |

- |

0.10 |

- |

Single |

Total |

Remain |

|

0.05 |

0.15 |

|||||||||

|

Alloy & Temper |

Tensile strength Rm/Mpa |

Yield strength Rp0.2/Mpa |

Elongation % |

Earring |

|

3104-H19 |

290-320 |

265-290 |

≥4 |

≤2.5 |

Resists cracking during stretching, enabling high success rates for complex shapes in a single forming.

Withstands salt spray and weak acids/alkalis, remaining rust-free for 3-5 years in humid environments.

Laser/TIG welds exhibit high joint strength without porosity or brittleness risks.

More affordable than 3004/5052 alloys while outperforming pure aluminum coils.

No heavy metal leaching, certified for food contact, and compliant with industry standards.

"We manufacture can lids, and previously, pure aluminum lids often led to complaints about ‘seal leakage’ and ‘burred edges causing cuts,’ resulting in high defect rates. After switching to 3104 aluminum coil, our sealing qualification rate soared to 98%! Its stamping ductility is incredible—even at 0.2mm thickness, it forms flawless threads with edges so smooth our inspectors were impressed."