Stock code: 601677

Stock code: 601677

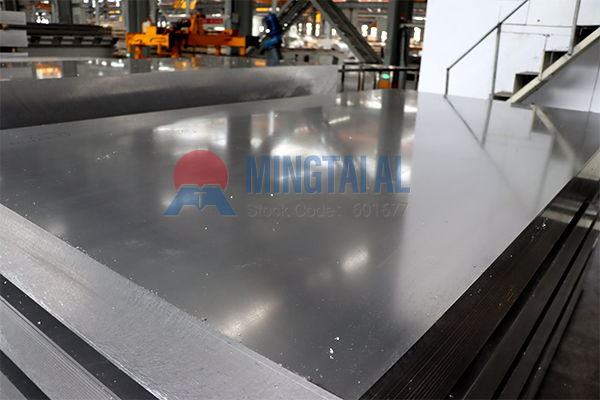

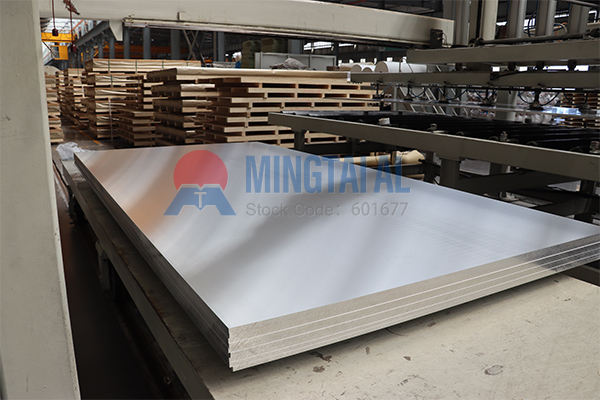

7075 Aluminum Plate is an Al-Zn-Mg-Cu series alloy that can be heat-treated for strengthening. Zn and Mg primarily contribute to its strength, while Cu enhances the alloy's corrosion resistance.

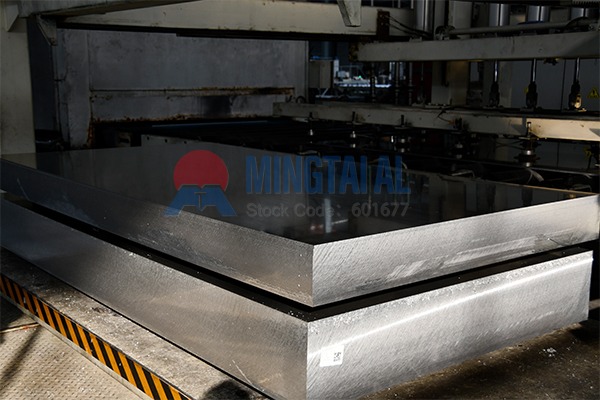

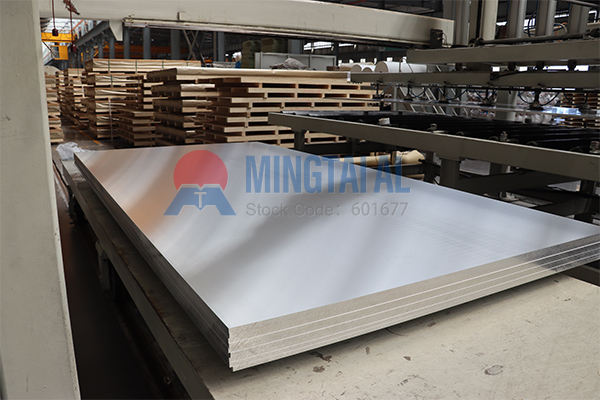

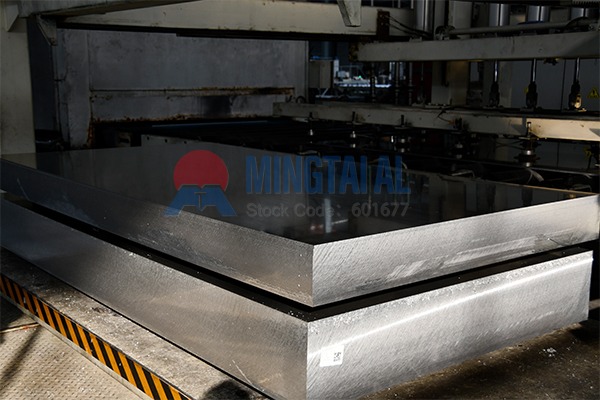

7075 Aluminum Plate is an Al-Zn-Mg-Cu series alloy that can be heat-treated for strengthening. Zn and Mg primarily contribute to its strength, while Cu enhances the alloy's corrosion resistance. The 7075 aluminum plate is an ultra-high-strength aluminum alloy with excellent mechanical properties, featuring tensile and shear strengths exceeding 600 MPa and an elongation rate of up to 70%.

For the relatively high-hardness 7075 aluminum plate, strict attention is paid to product quality during production, enabling the manufacturing of various tempers such as O, T6, and T651. Mingtai’s 7075 aluminum plates can be used to produce molds, such as shoe molds. If you would like to learn more about the applications of 7075 aluminum plates, Mingtai Aluminum welcomes your visit.

1. Aerospace: Used in critical load-bearing components such as aircraft wings, fuselage frames, helicopter rotors, and drone fuselage structures.

2. High-End Manufacturing: Precision molds (e.g., injection molds, die-casting molds), automotive suspension systems, and high-speed train components.

3. Sports Equipment: Lightweight, high-strength applications like mountain bike frames, rock-climbing gear, and snowboards.

|

Alloy |

7075 |

|

Temper |

F, O, T6, T651 |

|

Thickness(mm) |

20--500; customizable |

|

Width(mm) |

200-2600, customizable |

|

Length(mm) |

500-16000, customizable |

|

Application |

Golf heads, molds, shoe molds, precision parts, etc. |

|

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Zr |

Others |

AL |

|

7075 |

0.40 |

0.50 |

1.2-2.0 |

0.30 |

2.1-2.9 |

0.18-0.28 |

5.1-6.1 |

0.20 |

-- |

0.20 |

Balance |

Tensile strength comparable to steel, making it ideal for high-stress structural parts.

Density only 1/3 that of steel, significantly reducing equipment weight.

Supports CNC precision cutting, hot forging, cold rolling, and other processes to meet complex structural needs.

Maintains structural stability under high-cycle loads, extending service life.

More affordable than titanium alloys while meeting performance requirements, widely replacing traditional metals.

"Our factory used 7075 aluminum plates for drone fuselage frames, and the results exceeded expectations! We initially worried about insufficient strength, but its load-bearing capacity surpassed steel while being 40% lighter, directly improving flight endurance. Additionally, machining was smooth with no burring issues, eliminating the need for secondary polishing. Although the price is higher than standard aluminum, the reduced material waste and lower transportation costs actually lowered overall expenses—truly outstanding value for money!"